Forthcoming steam weekends (2026): 18-19 April 2026; 13-14 June 2026; 13 September 2026; 19 September 2026; 10-11 October 2026

Opening hours at other times: from 04 April 2026 to 24 October 2026 every saturday from 10 am to 5 pm.

Further information is available here.

Opening hours at other times: from 04 April 2026 to 24 October 2026 every saturday from 10 am to 5 pm.

Further information is available here.

18-19 April 2026: Saisoneröffnung

News

02.02.2025: Work on the boiler of our steam locomotive

We have already reported on the work on our steam locomotive 50 3570 in recent newsletters. The main focus is still and for the foreseeable future on the necessary repair work on the boiler, which must be prepared.At the beginning of the year, we had already started to remove the so-called superheater elements from the locomotive's boiler. These are pipes through which the steam flows on its way to the cylinders and is heated to nearly 300 degrees Celsius. This increases its efficiency. Loosening and removing the pipes is one of the hardest and dirtiest jobs on the locomotive, because you are exposed to the soot and rust of recent years and the pipes are heavy and unwieldy. Fortunately, this work has now been completed and the smokebox, i.e. the part of the boiler under the chimney, is now completely empty.

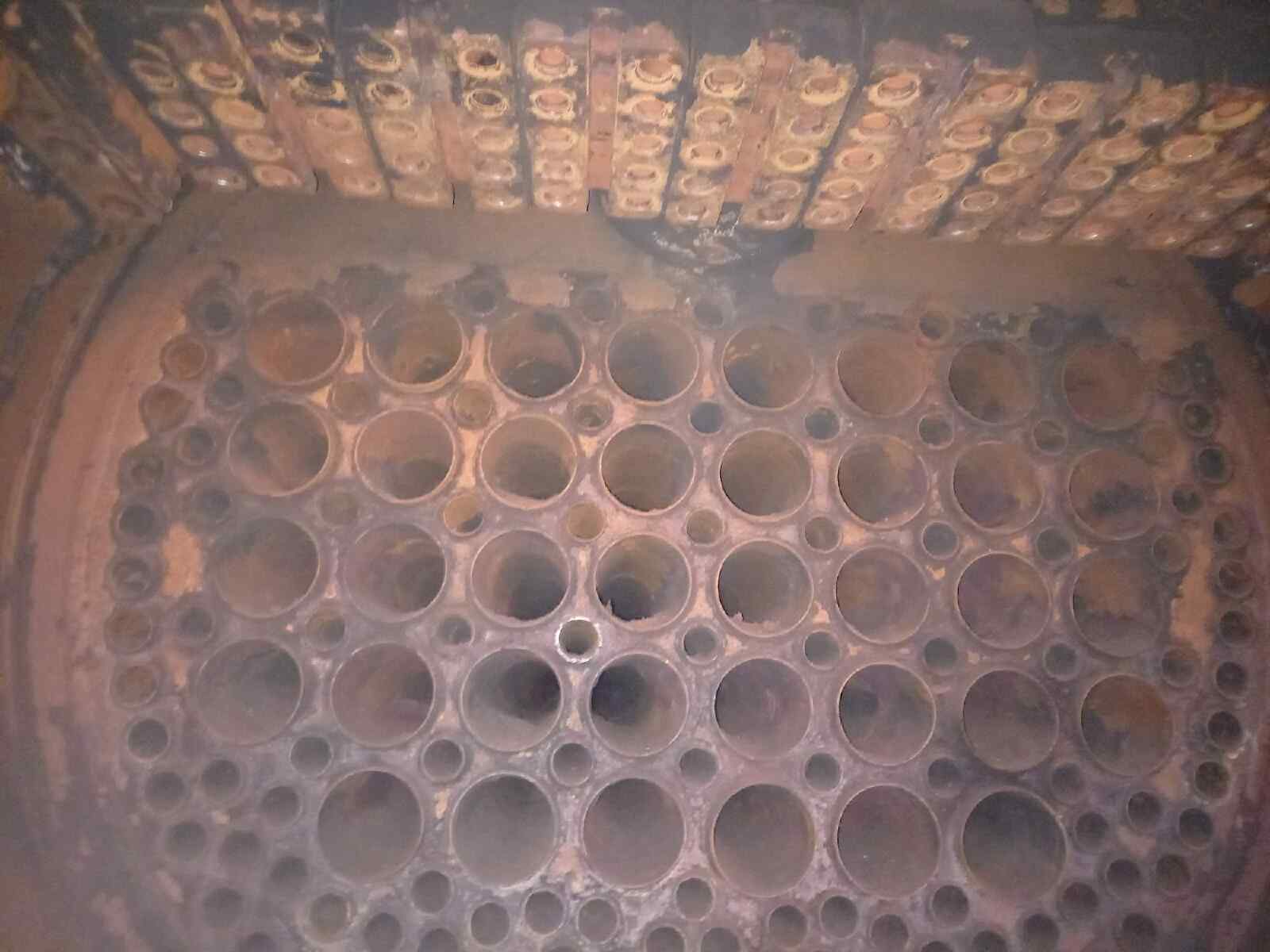

In the first picture, you can also see a round wall at the end of the smokebox, in which dozens of holes can be seen. On closer inspection, you can see that a pipe ends in each of the 38 large and over 100 small holes.

The hot air and exhaust fumes from the fire burning at the other end of the boiler in the firebox flow through these pipes. The hot air therefore heats the tubes from the inside. There is also such a similar wall in the firebox. Between these walls and in the spaces between the pipes, there is water when the locomotive is in operation, which is boiled into steam by the heated pipes. This is the steam that moves the locomotive.

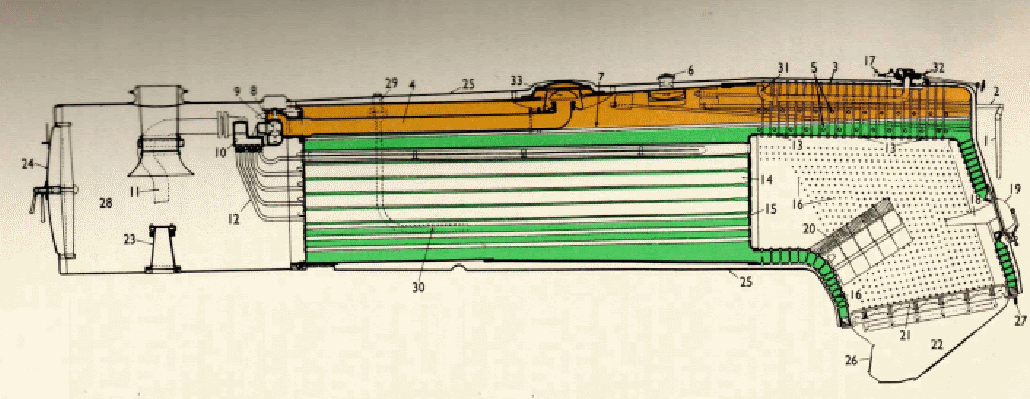

The following picture shows a sectional drawing of a boiler similar to the one on our steam locomotive 50 3570. The superheaters are marked with the numbers 12, the pipes in the boiler with the numbers 14 and 15, and the green colour indicates the space in the boiler where water is heated to steam when the locomotive is in operation. The space in which the steam collects above the water level is marked in orange. The smokebox (No. 28) is on the left-hand side of the drawing, the firebox (No. 16) on the right-hand side.

Now you can imagine that the pipes mentioned are exposed to a very high thermal load from the inside and to contact with water from the outside, which causes them to rust and gradually wear away. The pipe walls therefore become thinner over time. As it is essential to avoid the situation where pipes become perforated or even burst, they have to be replaced with new ones after a few years. And that's exactly what we plan to do again so that the boiler can be operated safely for the next few years.

Once the superheaters had all been removed, the work shifted to the firebox. Here, the so-called brick arch (no. 20) had to be dismantled. This is a round arch made of fireclay bricks, which is intended to prevent the flames in the firebox from hitting the pipe wall located there directly. To do this, you have to climb into the firebox through the fire door (No. 19) on the driver's cab of the locomotive, which is only possible if your waist and shoulder width do not exceed a certain size.

Once the brick arch had been removed, there was now enough space to devote to removing the pipes in the boiler. It should be noted that the tubes are only welded into the tube wall at one end, namely in the firebox. At the front end, in the tube wall in the smokebox, they are merely rolled in, i.e. mechanically widened with enormous force to such an extent that they are tightly stuck in the tube wall, but not firmly connected. The reason for this is that the entire boiler and the tubes inside it become several millimetres longer or shrink when the fire in the firebox goes out and the boiler is taken out of operation. In order to avoid tension in the tubes, they can push through the tube wall a little at the rolled-in end when heating up and cooling down. If this were not the case, they could buckle when heating up or even tear when cooling down.

Now, our task is to burn away the weld seams of all the pipes in the firebox with a welding torch and grind away the residue to release the pipes on this side.

Then, and this is when it gets really intense, the pipes are driven forwards towards the smokebox using a kind of pneumatic hammer so that the end rolled in at the front comes out of the pipe wall and the pipes are loose there too. Then you can pull them out completely at the front and replace them with new ones later. But it will be some time before then and until then the whole project will only cost our labour.

After that, it will unfortunately be very expensive, because the cost of making a new pipe alone - depending on the diameter - can run to several hundred euros each. If you consider that we are talking about 170 pipes, this alone adds up to a considerable amount. Then there is the installation by a specialist contractor that is authorised and certified to work on pressure vessels such as our boiler.

And this is where you come in: If you would like to support us in getting our steam locomotive back into operation, you can help us with a donation, no matter how big it is. Every euro helps. Become a pipe sponsor. Feel free to contact us if you have any questions. The members of our Executive Board will be happy to answer your questions.

What else has actually happened?

The work in our carriage 197 805 is continuing. At the moment, the walls are being painted so that the luggage racks can be installed soon. We will then turn our attention to the heating and the floor covering.

We are also currently working on our access road. If you have visited us before, you may remember the wooden planks that were fixed between the rails on the way from the gatehouse to the engine shed to ensure a crossing. These planks have now been worn out by heavy vehicles and need to be replaced. The new solution consists of paving the level crossings, which should be much more durable.

vehicle: 50 3570-4

related articles (News):

related articles (Press):

Dampflokfreunde Salzwedel e.V. Am Bahnhof 6, 19322 Wittenberge

News of our museum

News of our museum We are working on the boiler of our steam locomotive 50 3570

We are working on the boiler of our steam locomotive 50 3570 Work and pleasure at the start of the year

Work and pleasure at the start of the year Christmas wishes

Christmas wishes News from the locomotive shed

News from the locomotive shed The winter work begins

The winter work begins Late summer news from the engine shed

Late summer news from the engine shed News from the engine shed

News from the engine shed News from Wittenberge

News from Wittenberge Neue Partner für den Historischen Lokschuppen

Neue Partner für den Historischen Lokschuppen Historischer Lokschuppen ruht

Historischer Lokschuppen ruht Lok 50 3570-4 im Rampenlicht

Lok 50 3570-4 im Rampenlicht Operation am Herzen einer Lok

Operation am Herzen einer Lok