Forthcoming steam weekends (2026): 18-19 April 2026; 13-14 June 2026; 13 September 2026; 19 September 2026; 10-11 October 2026

Opening hours at other times: from 04 April 2026 to 24 October 2026 every saturday from 10 am to 5 pm.

Further information is available here.

Opening hours at other times: from 04 April 2026 to 24 October 2026 every saturday from 10 am to 5 pm.

Further information is available here.

18-19 April 2026: Saisoneröffnung

News

20.12.2022: Review of the past season

Dear readers of our news, once again a year has passed and once again one wonders how it could happen so quickly. For us, at any rate, it was an entertaining year that we look back on with pleasure. After the Corona-related declines in attendance over the past two years, we had a successful season. This shows us that you have not forgotten us, but actively support us through your visit. The many friendly faces also confirm to us that you enjoy visiting us and that we have something to offer you.In the following we show you a few pictures from this year, which have remained in our lasting memory. Exemplary for the maintenance measures on our infrastructure, the following picture reminds us of lots of track construction so that we can continue to drive safely over our property in the future.

The visible progress on our coach 197 805 in the form of a new paint job is a reminder of the work done on our vehicles.

Locomotives large and small passed the season with flying colors and provided trouble-free service.

We remember the numerous visitors to our locomotive shed festivals, of which there will be three again next year. You can already find the dates on our homepage ( https://dampflok-wittenberge.de/terminplan ). Please reserve one or the other date in your personal calendar and contact your friends and relatives.

We also remember one or the other star on our premises and thank all contributors that many a long-cherished wish could come true. Here the 01 509 of the Pressnitztalbahn.

After the last event, a rainbow pointed exactly to our locomotive shed. We see this as a good omen that the future will bring us success.

Of course, success is even greater when everyone pitches in. Only then can we move forward. Perhaps you would like to help out? You can do this in several ways: You are welcome to lend a hand on site. You can also work in the "home office" by writing texts or researching the history of the museum and its vehicles. Or you can support us with your donation ( https://dampflok-wittenberge.de/content_spende ). Because every Euro helps us to realize our next goals. Please contact our board if you have any questions or suggestions info@dampflok-wittenberge.de.

At the end of our little review of the year, we would of course like to send you our Christmas greetings. We wish you a pleasant holiday season and a happy new year. We will continue to inform you here, on Instagram and via our Youtube channel about news and with glimpses behind the scenes.

Stay in touch with us!

Yours

Dampflokfreunde at the

Historischer Lokschuppen Wittenberge

12.12.2022: Behind the scenes, part 2: Our service water supply

A few weeks ago, we already took a look at our water tower for you, dear readers. There you saw the large storage tank where the water for our steam locomotives is kept.Today we want to show you where this water comes from. For this we have two "sources" that date back to the early days of the railway depot in the late 19th century. On the one hand, there is an underground inflow from the little river Stepenitz, which runs behind the railway tracks on the Berlin side. An underground canal leads from this river to the locomotive shed area. It ends near the water tower in a deep shaft. Electric pumps are installed here to pump the water into the tower.

On the following picture you can see the course of the canal, indicated by a dashed line (picture source: Google Earth).

Unfortunately, the tunnel must have been damaged during the railway expansion in the early 2000s. It may have partially collapsed, because there is relatively little water left.

Therefore, we mostly help ourselves from the well on the museum grounds. The well shaft is located right next to the water tower. Visitors may notice here the brick rim of the shaft, which is covered with planks. In the meantime, a small fence has also been built around the shaft.

Next to the well shaft is the pump shaft. This shaft had been filled in with rubble and earth at the end of the 1990s because the water supply via the well was no longer needed. We uncovered it again after the opening of the museum and built a rather inconspicuous hut over it.

Let's take a look inside.

We can see a shaft about four metres deep, with a base area of four by four metres. We have built a new staircase, restored the suction pipe from the well shaft and installed an electric pump.

We also installed an electric chain hoist, which makes it much easier for us to change the pump.

This way we are independent of the public water supply. For the chemists: Our water has a hardness (lime content) of 14.6° dH.

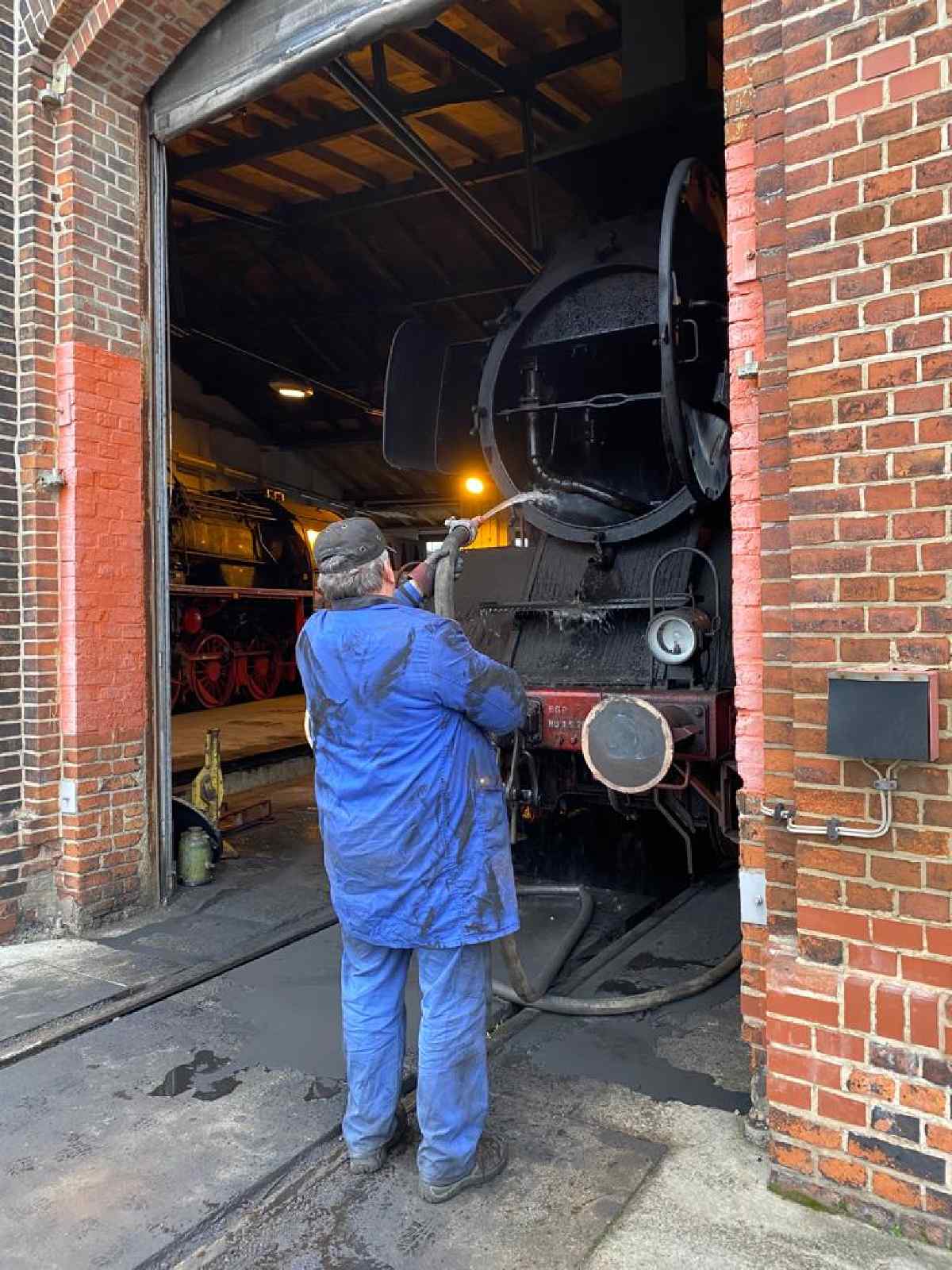

What else happened this weekend? After the end of the season, our operational vehicles have to be put into hibernation. Therefore, the boiler of the 50 3570 was washed out on Saturday. This means that the residues left behind in the boiler when the water evaporated are washed out with a sharp jet of water.

The deposits are mainly limescale, as you know it in miniature from your kettle or washing machine. To prevent the limescale from settling firmly on the surfaces, you might use limescale remover in the form of tablets at home. We use soda ash for this, which is added to the water in the tender in powder form and dissolves there. From there it gets into the boiler when the locomotive is running and there it binds with the lime from the water to form sludge, which settles at the bottom of the boiler. Since soda ash foams quite a bit and this is undesirable when operating the locomotive, a so-called foam brake is also added to the water. Locomotive crews can see how much soda has to be added by looking at the water cranes. It should be written there how hard, i.e. how calcareous the water is. Corresponding tables provide information on how much soda must be added for which water hardness.

In the following pictures you can see some active people washing out the boiler of steam locomotive 50 3570 and the muddy water running out of the boiler.

04.12.2022: Almost like in the days of the German Reichsbahn

Last week, steam locomotive 01 509 had to be fired up, because it was supposed to haul a speial train from Plauen to Wernigerode on Saturday. This, as some may know, is not so easy. In order to put the oilfired locomotive into operaion, a steam donor is needed, this time in the form of our steam locomotive 50 3570.So, early Wednesday morning, the coal-fired steam locomotive 50 3570 was fired up first.

After this locomotive was under steam, it was coupled to 01 509 and the heating lines of the two locomotives were connected. On the following picture you can see the heating line under the buffers between the two locomotives

Then, over a period of several hours, steam was pumped from 50 3570 into 01 0509. This steam was first used to preheat the 01's heavy oil supply to about 60 degrees so that the oil would become liquid. In addition, the water in the locomotive's boiler was slowly warmed up. After a few hours, the 01's oil burners were finally put into operation to inject the now liquid heavy oil into the locomotive's combustion chamber. The resulting oil mist was ignited with a fuse, thus lighting the fire in the 01's boiler. The burners then had to work for several hours to heat the water in the locomotive's boiler and bring the boiler up to the necessary operating pressure.

After several hours, 01 509 then had the necessary steam pressure to be able to move under its own power.

How the heating of the 01 509 works, we have also shown in a small film. You can find it on our Youtube channel or under the following link:

https://youtu.be/9SjOIgxeMac

What else happened?

Last Saturday, we could start with the winter maintenance of our steam locomotive 50 3570. First, the water was drained from the boiler and the tender to avoid frost damage and to be able to wash out the boiler.

The interior work on our car 190 805 progressed with clearly visible steps. Here, the new plywood ceiling paneling could be installed.

And of course there are always some "little things" to do. In the dark season, for example, it is immediately noticeable when lamps are defective. The colleague who is free from giddiness then has to climb to lofty heights to change the bulbs.

vehicle: 50 3570-4

related articles (News):

related articles (Press):

12.11.2022: A look behind the scenes

Now that the museum season of 2022 has ended, we begin today with a casual series of glimpses behind the scenes. We report on places or incidents that a visitor would not normally get to see. Today we turn our attention to the water tower at the back of our museum grounds, which was built in 1898.

The striking structure consists of three main parts, only two of which are visible from the outside. It serves to supply steam locomotives, which need lots of water to produce steam and which has to be "refueled" regularly. The wide upper part of the tower houses a steel tank that can hold about 200 m³ of water. Since the tank is at a height of 12 meters, the water pressure at the bottom of the tower is therefore a little more than one bar, depending on how high the tank is filled. Let's take a look inside together:

If you open the entrance door, you get into the shaft of the tower. Here you can see thick pipes in the middle that reach vertically from the floor to the ceiling. There are three pipes in total. Groundwater from our well system is pumped up into the storage tank through one of them. Through the other two pipes, water rushes down from the storage tank when one of the three water cranes located in the compound is opened.

Courageous museum staff who are free from giddiness can climb up a steel ladder in the tower. However, for safety reasons, please do not try this yourself the next time you visit our museum and the door of the tower should be open.

Above the false ceiling you reach the storage tank. Another staircase leads up to the top of the tank.

The third part of the tower is underground. Here there is a basement where the risers and downpipes lead through the thick walls into the soil outside and then on to the water cranes in the grounds. The technology of the water tower and the entire water supply system was restored to working order by our volunteers after the museum opened, so that today we can once again show you an authentic supply of our steam locomotives. More details next time.

There are other pleasing things to report. As you may have followed, the museum has been in possession of the sidecar 190 851 for about three years. It is an old Prignitzer, because it was used for decades on branch lines around Perleberg and thus in our nearest neighbourhood. After the closure of the lines, it was relocated to Berlin and served as a service vehicle for the (East) Berlin construction office and the Deutsche Reichsbahn. It was last stored in a warehouse of the Berlin Museum of Transport and Technology. This museum was kind enough to let us have the vehicle. We recall that it arrived in Wittenberge in mid-December 2019 with faded paint, but still on its own wheels.

Now the sheet metal work on the car body could be completed and the painting finished. Today the first roll out took place to see its new shiny paint in daylight.

In the medium term, the wagon should be ready for operation again so that it can transport you, dear visitors. However, there is still a long way to go. First of all, some of the windows have to be made of safety glass, and the interior, seats and floor need to be freshened up. Technically, axles and brakes, buffers and draw hooks need to be checked. We also want to install a modern autonomous heating system so that it can also be operated on cooler days. Perhaps a system from the bus or motorhome sector. If you have ideas or even parts for this, please feel free to contact us. We are grateful for any help.

vehicle: 190 851-6

related articles (News):

related articles (Press):

22.10.2022: After the season is before the season.

Today, Saturday, the museum was open for the last time this year. Quite a few visitors took this opportunity to pay us another visit. Thank you very much for coming this year.The active members were busy preparing some locomotives for the winter. Thus, all steam locomotives were stripped of their slag and their fireboxes and smokeboxes were thoroughly cleaned. In the case of the steam locomotive Emma, the boiler was also washed out because lime scale builds up on its inside during operation. You may know this from your kettle or the heating rod of your washing machine at home. The limescale must be removed from time to time. To do this, all the washing hatches in the boiler are opened and the boiler is washed out with a sharp jet of water.

The following picture shows the colleague opening a hatch on the top of the boiler.

After rinsing, the result shows: lime residues are flushed out of the boiler

At 50 3570, the check valves have been removed. They are used to seal the lines through which fresh water can be fed into the boiler during operation. The valves consist of two parts: On the one hand, a housing with a sealing edge in it, and on the other hand, the actual valve body. The latter converges conically at the end and is pressed against the seat in the housing by the steam pressure in the boiler. If a pump is now turned on, the valve body is lifted out of the seat by the pump pressure and water can flow through the gap. The parts are made of brass to prevent them from rusting. However, brass is a relatively soft metal. Thus, closing the valve can cause a furrow to form in the valve body when it is pressed back onto the seat. This will cause the valve to leak over time. Valve bodies and seats must therefore be regularly reworked on the lathe. Here are a few pictures of the removal and machining of a valve and a comparison before and after machining.

Unfortunately, diesel locomotive 0604 developed an oil leak after the end of the last event, which now had to be localized. Fortunately, it now turns out that only the pressure hose to the oil pressure gauge in the driver's cab had leaked.

Dear visitors, that was the report from this weekend. We will of course keep you updated, also during the winter break. If you would like to visit the museum during the winter break, it will be possible by arrangement. Please register by mail or telephone. Contact details for this can be found in the imprint of our website. The museum will reopen regularly on 8.4.2023. Thank you and see you soon!

vehicles: 50 3570-4, Emma, OHE 0604

related articles (News):

related articles (Press):

Dampflokfreunde Salzwedel e.V. Am Bahnhof 6, 19322 Wittenberge

News of our museum

News of our museum We are working on the boiler of our steam locomotive 50 3570

We are working on the boiler of our steam locomotive 50 3570 Work on the boiler of our steam locomotive

Work on the boiler of our steam locomotive Work and pleasure at the start of the year

Work and pleasure at the start of the year Christmas wishes

Christmas wishes News from the locomotive shed

News from the locomotive shed The winter work begins

The winter work begins Late summer news from the engine shed

Late summer news from the engine shed News from the engine shed

News from the engine shed News from Wittenberge

News from Wittenberge Neue Partner für den Historischen Lokschuppen

Neue Partner für den Historischen Lokschuppen Historischer Lokschuppen ruht

Historischer Lokschuppen ruht Lok 50 3570-4 im Rampenlicht

Lok 50 3570-4 im Rampenlicht Operation am Herzen einer Lok

Operation am Herzen einer Lok Final spurt before the Spring Festival

Final spurt before the Spring Festival Season opening

Season opening At full pressure

At full pressure More lamps and even more colour

More lamps and even more colour Sheet metal, paint and a few lamps

Sheet metal, paint and a few lamps All the best for the new year

All the best for the new year Latest Activities

Latest Activities Work on vehicles continues

Work on vehicles continues Maintenance work in full swing

Maintenance work in full swing Ein Stück Eisenbahnhistorie kehrt zurück

Ein Stück Eisenbahnhistorie kehrt zurück Christmas greetings from Wittenberge

Christmas greetings from Wittenberge Anstehen für eine Fahrt mit Emma

Anstehen für eine Fahrt mit Emma "Emma" geht, "Gartenlaube" ist da

"Emma" geht, "Gartenlaube" ist da Museumslok "Emma" ist wieder da

Museumslok "Emma" ist wieder da "Emma" geht auf Reisen

"Emma" geht auf Reisen Die erste Dampflok ist da

Die erste Dampflok ist da Restaurierte "Emma" schnauft nach 42 Jahren wieder

Restaurierte "Emma" schnauft nach 42 Jahren wieder